Inqubo eyisisekelo yokulungiselela izikhwama zokupakisha ezihlanganisiwe ihlukaniswe ngezinyathelo ezine: ukuphrinta, i-laminating, i-slitting, isikhwama sokwenza izikhwama, okuyizo izinqubo ezimbili ze-laminating nokwenza isikhwama yizinqubo ezibalulekile ezithinta ukusebenza komkhiqizo wokugcina.

Inqubo yokuhlanganisa

Ukuklama inqubo yokupakisha umkhiqizo, ngaphezu kokukhethwa okulungile kwezinhlobonhlobo zama-substrates, ukukhetha okunamathelayo okuyinhlanganisela nakho kubalulekile, ngokuya ngokusetshenziswa kwemikhiqizo, ukwakheka, izimo zangemuva kokucubungula, izidingo zekhwalithi zokukhethwa kwekhwalithi. Khetha i-adhesive engalungile, kungakhathaliseki ukuthi ubuchwepheshe bokucubungula obuhlanganisiwe buphelele kangakanani, kuzophinde kubangele imiphumela emibi, kanye nokucubungula ngemuva kokunciphisa amandla, ngaphansi kwamandla ahlanganisiwe, ukuvuza, izikhwama eziphukile nokunye ukwehluleka.

Ukukhethwa kokupakishwa kwamakhemikhali okuguquguqukayo kwansuku zonke nge-adhesives ukucabangela izici ezihlukahlukene, ngokuvamile, njenge-adhesive composite kufanele kuhlangabezane nezimo ezilandelayo.:

Ayinabuthi

Akukho okukhishwe okuyingozi okuvela ngemva kokupakisha uketshezi.

Isebenza ezidingweni zokushisa zokugcina ukudla.

ukumelana nesimo sezulu esihle, akukho okuphuzi kanye namabhamuza, akukho chalking kanye delamination.

ukumelana namafutha, ama-flavour, uviniga notshwala.

Akukho ukuguguleka kukayinki wephethini yokuphrinta, okulindeleke ukuthi ube nokuhlobana okuphezulu kukayinki.

Ngaphezu kwalokho, ukumelana nokuguguleka, okuqukethwe kuqukethe inani elikhulu lezinongo, utshwala, amanzi, ushukela, ama-fatty acids, njll., izakhiwo zabo ziyahlukahluka, kungenzeka kakhulu ukuthi zingene ngesendlalelo sangaphakathi sefilimu ehlanganisiwe ibe ungqimba olunamathelayo, okubangela ukulimala kokugqwala, okuholela ekuqothulweni kwesikhwama sokupakisha, ukulimala kokwehluleka. Ngenxa yalokho, i-adhesive kumele ibe nekhono lokumelana nokuguguleka kwezinto ezingenhla, ihlale igcina amandla okwanele e-adhesive peel.

Izindlela zokucubungula ifilimu yepulasitiki yindlela eyinhlanganisela eyomile, indlela eyinhlanganisela emanzi, indlela yenhlanganisela ye-extrusion, indlela yenhlanganisela eshisayo encibilikayo kanye nendlela yenhlanganisela ye-co-extrusion nezinye ezimbalwa..

1, Ukuhlanganisa okomile

I-Dry lamination method iyindlela evame kakhulu yokufaka i-plastic packaging lamination. Ngaphansi kwezimo ezithile zokushisa, ukungezwani kanye nesivinini, i-substrate yokuqala igcwele ngokulinganayo ungqimba lwe-adhesive-based adhesive (i-adhesive eshisayo encibilikisa ingxenye eyodwa noma i-adhesive-component reactive adhesive), ngemva komshini wokubhaka we-laminating (ihlukaniswe yaba izingxenye ezintathu: indawo yokuhwamuka, indawo yokuqina kanye nokukhishwa kwendawo yokuphunga, ukucindezela, ukuhwamuka kwe-solvents) esimweni sokucindezela okushisayo kanye ne-substrate yesibili (ifilimu yepulasitiki, iphepha noma i-aluminium foil) ihlanganiswe ibe ifilimu eyinhlanganisela.

I-lamination eyomile ingalaminate noma yiluphi uhlobo lwefilimu, futhi ingathatha indawo yekhono lokuhlanganisa izinto zokupakisha ezisebenza kahle ngokwezidingo zenjongo kuye ngokuqukethwe. Ngakho-ke, ekufakweni, ikakhulukazi emaphaketheni amakhemikhali nsuku zonke kuye kwaxazululwa ukuthuthukiswa.

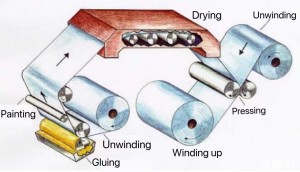

2,Ukuhlanganisa okumanzi

Indlela ehlanganisiwe emanzi iyinhlanganisela ye-substrate (ifilimu yepulasitiki, i-aluminium foil) ehlanganiswe nongqimba lwe-adhesive ebusweni, uma i-adhesive ayimile, ngokusebenzisa i-roller yokucindezela nezinye izinto (iphepha, i-cellophane) inhlanganisela, bese yomiswa ngemva kwehhavini ibe yifilimu eyinhlanganisela.

Inqubo yenhlanganisela emanzi ilula, inokunamathela okuncane, izindleko eziphansi, ukusebenza kahle kwenhlanganisela ephezulu, futhi ayifaki isincibilikisi esiyinsalela.

Umshini we-laminating ohlanganisiwe omanzi kanye nesimiso sokusebenza esisetshenziswayo kanye nendlela eyomile eyinhlanganisela ngokuyisisekelo iyafana, umehluko uyi-substrate yokuqala ehlanganiswe neglue, okokuqala nge-substrate yesibili ehlanganiswe ne-laminated composite, bese yomiswa kuhhavini. Isilinganiso esilula, esinamathelisi esincane, isivinini esihlanganisayo, imikhiqizo eyinhlanganisela ayinazo izincibilikisi ezisele, enye indlela yokungcola endaweni ezungezile.

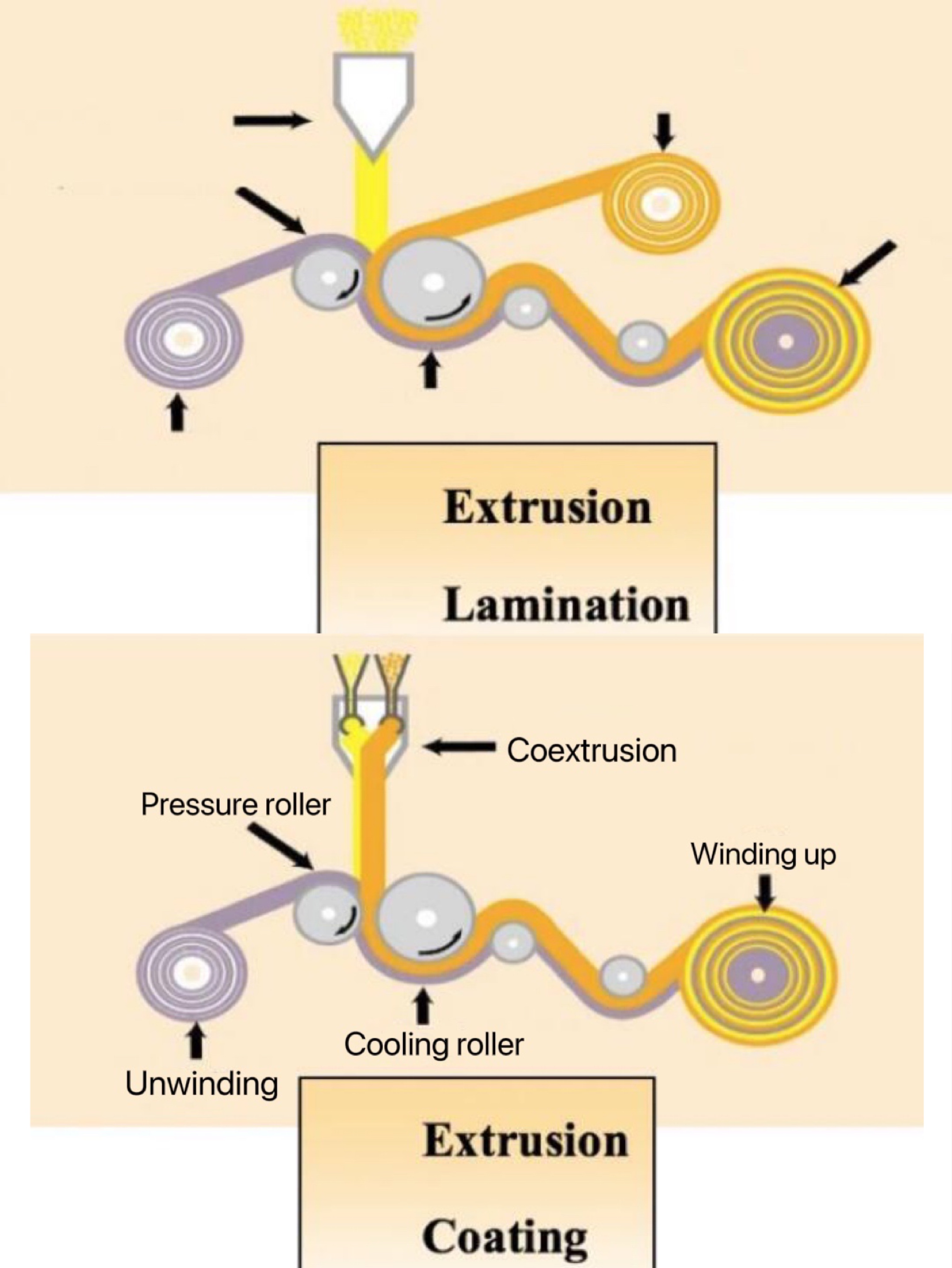

3. Ukuhlanganiswa kwe-Extrusion

I-Extrusion compounding iyindlela evamile kakhulu yokuhlanganisa inqubo, ukusetshenziswa kwe-resin ye-thermoplastic njengempahla eluhlaza, i-resin iyashiswa futhi inyibilike esikhunjeni, ngomlomo wokufa esikhundleni sokuphulukiswa kweshidi lefilimu, ngokushesha ngemva kokuhlanganiswa nolunye uhlobo noma amafilimu amabili ndawonye, bese epholiswa futhi ephulukisiwe. I-Multi-layer co-extrusion lamination iyinhlobonhlobo yezakhiwo ze-plastic resin ngokusebenzisa okungaphezu kwe-extruder co-extrusion, ku-die lamination kufilimu.

Izinto ezihlanganisiwe zijwayele izinkinga nezixazululo zekhwalithi

Ukuhlanganiswa kuyinqubo ebalulekile ekukhiqizeni nasekucubunguleni ukupakishwa okuguquguqukayo, ukwehluleka kwayo okuvamile yilezi: ukukhiqizwa kwamabhamuza omoya, ukushesha okuphansi kokuhlanganisa, imikhiqizo eqediwe eshwabene futhi igoqwe, imikhiqizo eyinhlanganisela yokwelula noma iyancipha, njll. Lesi sigaba sizogxila ekuhlaziyeni ukushwabana, imiphetho egoqiwe yezimbangela nezindlela zokuqeda.

1. Isimo sokushwabana

Ekuhlulekeni kwenhlanganisela eyomile yalesi simo kuthatha ingxenye enkulu yokwehluleka kuthinta ngqo ikhwalithi yokwenziwa kwesikhwama somkhiqizo ophelile.

Izizathu ezinkulu zalokhu kwehluleka yilezi ezilandelayo.

Izinga eliphansi lezinto eziyinhlanganisela noma i-substrate yokunyathelisa ngokwayo, ukuchezuka kobukhulu, amaroli efilimu ayaxega emikhawulweni yomibili futhi aqine ekugcineni ngenxa yokushuba kwamasondo okungalingani. Uma ivolumu yefilimu ihlukaniswa nokunwebeka kwenkulu, emshinini, ifilimu phezulu naphansi futhi kwesokunxele kanye nokubekwa kwe-amplitude kwesokudla nayo inkulu ngoba lapho impahla ingena phakathi kwesigubhu esishisayo nama-rollers ashisayo, ayikwazi ukulingana nama-rollers ashisayo, ngakho-ke ayikwazi ukucindezelwa phansi, okuholela ekuqedeni komkhiqizo oyinhlanganisela, ukushwabana komkhiqizo. Lapho izinto ezihlanganisiwe ziyi-PE noma i-CPP, uma ukuphambuka kokuqina kungaphezu kuka-10μm, kulula futhi ukushwabana, ngalesi sikhathi, ukungezwani kwezinto ezihlanganisiwe kungandiswa ngokufanele, futhi i-roller yokucindezela okushisayo ingaba yisimo esivundlile se-extrusion. Kodwa-ke, kufanele kuqashelwe ukuthi ukungezwani kufanele kube okufanelekile, ukungezwani okukhulu kulula ukwenza into eyinhlanganisela ibe yinde, okuholela ekutheni umlomo wesikhwama utshekele ngaphakathi. Uma ukuchezuka kobukhulu bezinto ezihlanganisiwe kukhulu kakhulu, angeke kusetshenziswe ngempela, kufanele kubhekwane nakho.

2. Amabala amhlophe ayinhlanganisela

Njengomphumela wezinga lokumbozwa kwe-inki elibi amabala amhlophe: kuyinki oyinhlanganisela omhlophe, lapho ukumuncwa kukayinki kuguquguquka kodwa kungaguquguquki okubangelwa amachashazi amhlophe, atholakalayo ukuze kuthuthukiswe umthamo wokomisa wendlela; uma kusekhona amachashazi amhlophe, ikhambi elivamile ukuthuthukisa ukumbozwa kweyinki emhlophe, njengokuhlola ukucoleka kukayinki omhlophe, ngoba ukucoleka kokugaya kwezinga lokufakwa kukayinki omuhle kunamandla.

I-Adhesive esikhundleni samachashazi amhlophe akhiqizwe ngokungalingani: kungqimba lukayinki olumbozwe ngeglue, ngenxa yokungena kukayinki kuzomunca i-solvent, ukungezwani kwendawo futhi kuncane kune-substrate, ukulinganisa akulungile neze njengefilimu ekhanyayo ehlanganiswe neglue, i-glue depressions kanye ne-aluminium-plated surface noma i-aluminium foil ayiyona into eseduze, ebonisa ukukhanya okukhanyayo noma i-dibble yamabala amhlophe. Isixazululo singasetshenziselwa ukushelela ukugqoka nge-roller ye-rubber efanayo, noma ukwandisa inani lokushintshwa.

3. Ibhamuza elihlanganisiwe

Amabhamuza ahlanganisiwe akhiqizwa ezimweni ezilandelayo nezindlela ezihambisanayo.

Amabhamuza ayinhlanganisela kumkhuba

1. ifilimu embi, kufanele ithuthukise ukugxila kokunamathela kanye nenani lokushintshwa, i-MST, i-KPT ebusweni akulula ukumanzisa, kulula ukukhiqiza ama-bubbles, ikakhulukazi ebusika. Amabhamuza omoya kuyinki,kungabasebenzisa indlela yokwandisa inani le-adhesive ukususa.

2,Iqhubu nebhamuza likayinki, kufanele kuhlanganiswe izinga lokushisa elihlanganisa ifilimu kanye nokucindezela okuhlanganisiwe ukuze kwande.

I-3, Inani lokwengeza i-glue ebusweni bukayinki liphansi, kufanele likhulise isikhathi sokunamathisela i-roller pressure kanye nokusetshenziswa kwama-roller abushelelezi, ukushisa kwefilimu okwanele ukunciphisa isivinini sokuhlanganisa, khetha i-glue enhle yokumanzisa kanye nokukhetha okulungile kweyinki.

4. Izithasiselo (i-lubricant, i-agent ye-antistatic) efilimini zingenwa yi-glue, ngakho-ke kufanele ukhethe i-glue enesisindo esiphezulu samangqamuzana nokuphulukiswa okusheshayo, ukwandisa ukugxila kweglue, ukuphakamisa izinga lokushisa kuhhavini ukuze usule ngokugcwele iglue, futhi ungasebenzisi ifilimu enezinyanga ezingaphezu kwezingu-3 zokubeka isikhathi, ngoba ukwelashwa kwe-corona kulahlekile.

5,Izinga lokushisa ebusika liphansi, ukuhlanganiswa kwefilimu nokudluliswa kweyinki, ukusetha kabusha umphumela wokuqondanisa akukuhle, ngakho indawo yokusebenza igcina izinga lokushisa elithile.

6,Izinga lokushisa lokumisa liphezulu kakhulu, i-blistering ye-adhesive noma i-crusting yesikhumba esingaphezulu kwenzeka, futhi ngaphakathi akusomile, ngakho-ke izinga lokushisa lokumisa lokunamathisela kufanele lilungiswe.

7. Umoya ufakwe phakathi kwefilimu ye-rollers ehlanganisiwe, izinga lokushisa lama-rollers ahlanganisiwe kufanele linyuswe futhi i-angle ehlanganisiwe kufanele ihlakazwe (ifilimu inzima futhi kulula ukukhiqiza ama-bubbles uma inzima).

8,Ngenxa yesithiyo sefilimu ephezulu, igesi ye-CO2 ekhiqizwe ukuphulukiswa okunamathelayo, okusele kufilimu eyinhlanganisela, engaphrintiwe ku-bubble, kufanele ithuthukise inani le-ejenti yokwelapha, ukuze ingcina yokwelapha isomile.

9. I-glycolic acid ku-raber iyi-solvent enhle yokugcwalisa inki, i-rubber incibilikisa uyinki, futhi kukhona amabhamuza kuphela kuyinki, okufanele agweme ukungena kwamanzi ku-rubber futhi athuthukise izinga lokushisa lokumisa le-rubber ukunciphisa ukuchithwa kweyinki.

4, Amandla e-peel abuthakathaka

Amandla e-peel ampofu, ngenxa yokuphulukiswa okungaphelele, noma inani leglue lincane kakhulu, noma inki esetshenzisiwe ne-adhesive ayihambisani nesimo, nakuba ukuphulukiswa sekuqediwe, kodwa phakathi kwezingqimba ezimbili zefilimu eyinhlanganisela ngenxa yokuntuleka kobude kuye kwanciphisa ukuncishiswa kwamandla.

Inani lomjovo weglue lincane kakhulu, isilinganiso se-adhesive sincishisiwe, i-glue iyawohloka endaweni yokugcina, amanzi notshwala kuhlanganiswa ku-glue, abasizi befilimu bayancishiswa, inqubo yokomisa noma yokuvuthwa ayikho, njll.

Naka isitoreji esifanele se-glue, isikhathi eside kakhulu asikho ngaphezu konyaka ongu-1 (i-tin ingavalwa); vimbela izinto zangaphandle ukuthi zingangeni ku-glue, ikakhulukazi amanzi, utshwala, njll, okungabangela ukwehluleka kweglue. Ifilimu efanelekile yokuthuthukisa inani le-glue enamathela; thuthukisa ivolumu yomoya wokushisa okomisa, unciphise ijubane lokuhlanganisa. Ukwelashwa kwesibili kwendawo yefilimu ukuthuthukisa ukungezwani kwendawo; ukunciphisa ukusetshenziswa kwezithasiselo endaweni ehlanganisa ifilimu. Zonke lezi zindlela zingasisiza ukuba sithuthukise inkinga yokungaqini kahle kwekhasi lenhlanganisela.

5. Ukushisa uphawu kubi

Isikhwama esihlanganisiwe sokushisa seal ukusebenza okubi futhi izimbangela zakhona ngokuyisisekelo yizimo ezilandelayo.

Amandla okuvalwa kokushisa mancane. Izizathu eziyinhloko zalesi simo azelapheki ngokuphelele noma izinga lokushisa lokuvalwa kokushisa liphansi kakhulu. Lungiselela inqubo yokwelapha noma ukhuphule izinga lokushisa lommese wokuvala ngokufanelekile kungathuthukisa inkinga.

I-Delamination yekhava yophawu lokushisa kanye nenkomba ye-refractive. Isizathu esiyinhloko salesi simo ukubopha ayelashwa. Lungisa isikhathi sokwelapha noma ulungise okuqukethwe komenzeli olaphayo kungathuthukisa le nkinga.

Ukungavuleki kahle / ukungavuleki kahle kwefilimu yongqimba yangaphakathi. Imbangela yalesi simo i-ejenti yokuvula encane kakhulu, eholela ekusetshenzisweni okuningi (isilungisi) kanye nendawo yefilimu enamathelayo noma enamafutha. Le nkinga ingathuthukiswa ngokwandisa inani le-ejenti yokuvula, ukulungisa inani lesilungisi, nokugwema ukungcoliswa kwesibili endaweni yefilimu.

Isiphetho

Siyabonga ngokufunda kwakho, sithemba ukuthi sinethuba lokuba ozakwethu.

Uma unombuzo ofuna ukuwubuza, sicela ukhululeke ukusazisa futhi usithinte.

Othintana naye:

Ikheli le-imeyili :fannie@toppackhk.com

WhatsApp : 0086 134 10678885

Isikhathi sokuthumela: Apr-01-2022