Inkqubo esisiseko yokulungiselela iingxowa zokupakisha ezidibeneyo ihlukaniswe ngamanyathelo amane: ukuprinta, ukunyanyiswa, ukutyunjwa, ukwenza isikhwama, apho iinkqubo ezimbini ze-laminating kunye nezikhwama zokwenza iinkqubo eziphambili ezichaphazela ukusebenza kwemveliso yokugqibela.

Inkqubo yokudibanisa

Ukuyila inkqubo yokupakisha imveliso, ngaphezu kokhetho oluchanekileyo lweentlobo ezahlukeneyo ze-substrates, ukhetho lwe-adhesives composite nayo ibaluleke kakhulu, ngokuhambelana nokusetyenziswa kweemveliso, ukubunjwa, iimeko zasemva kokulungiswa, iimfuno zomgangatho wokukhethwa komgangatho. Khetha i-adhesive engalunganga, kungakhathaliseki ukuba iteknoloji yokucubungula i-composite, nayo iya kubangela imiphumo emibi, kunye ne-post-processing ukunciphisa amandla, phantsi kwamandla adibeneyo, ukuvuza, iingxowa eziphukileyo kunye nokunye ukungaphumeleli.

Ukhetho lokupakishwa kweekhemikhali eziguquguqukayo zemihla ngemihla kunye ne-adhesives ukuqwalasela izinto ezahlukeneyo, ngokubanzi, njenge-adhesive composite kufuneka ihlangabezane nezi meko zilandelayo.:

Ayinatyhefu

Akukho zicatshulwa ziyingozi zivela emva kokupakisha ulwelo.

Isebenza kwiimfuno zobushushu bokugcina ukutya.

ukumelana nemozulu elungileyo, akukho tyheli kunye namadyungudyungu, akukho chalking kunye delamination.

ukumelana neeoli, iincasa, iiviniga kunye neealkoholi.

Akukho lukhukuliseko lwe-inki yoshicilelo lwepateni, ekulindeleke ukuba ibenobudlelwane obuphezulu be-inki.

Ukongeza, ukuchasana nokhukuliseko, umxholo uqulethe inani elikhulu leziqholo, i-alcohol, amanzi, iswekile, i-acids enamafutha, njl. Ngenxa yoko, i-adhesive kufuneka ibe namandla okuxhathisa ukukhukuliseka kwezinto ezingentla, ihlale igcina amandla aneleyo e-peel adhesive.

Iindlela zokusetyenzwa kwefilimu yePlasitiki yindlela eyomileyo edibeneyo, indlela emanzi edibeneyo, indlela ye-extrusion composite, indlela edibeneyo yokunyibilika eshushu kunye ne-co-extrusion composite indlela kunye nezinye ezininzi..

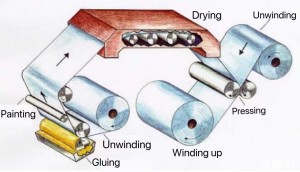

1, Ukudibanisa ukomisa

Indlela yokomisa i-lamination yeyona ndlela ixhaphakileyo yeplastiki yokupakisha i-lamination. Phantsi kweemeko ezithile lobushushu, ukuxinana kunye nesantya, substrate yokuqala izaliswe ngokufanayo kunye umaleko of ingcina-based ancamathele (enye-inxalenye eshushu yokuncamathelisa anyibilike okanye ezimbini-inxalenye encamathelayo reactive), emva laminating umatshini yokubhaka umjelo (yahlulwe yaba iindawo ezintathu: zone evaporation, ukuqina zone kunye nokukhutshwa kweendawo ezinevumba elibi, i-sombululo kunye ne-solvents zone, ngoko ke i-solvents iyaphuphuma) kwindawo yokushicilela eshushu kunye ne-substrate yesibini (ifilimu yeplastiki, iphepha okanye i-aluminium foil) ihlanganiswe kwifilimu edibeneyo.

I-lamination eyomileyo inokwenza i-laminate naluphi na uhlobo lwefilimu, kwaye ingathatha indawo yokukwazi ukudibanisa izinto zokupakisha eziphezulu zokusebenza ngokweemfuno zenjongo ngokuxhomekeke kumxholo. Ngoko ke, ekupakisheni, ngokukodwa kwi-package yemihla ngemihla yeekhemikhali iye yasombululwa uphuhliso.

2,Ukudibanisa okumanzi

Indlela yokudibanisa emanzi yi-substrate edibeneyo (ifilimu yeplastiki, i-aluminium foil) ifakwe ngomgca we-adhesive phezu komhlaba, kwimeko ye-adhesive ayimile, ngokusebenzisa i-roller yoxinzelelo kunye nezinye izinto (iphepha, i-cellophane) i-composite, kwaye yomiswa emva kwe-oven ibe yifilimu edibeneyo.

Inkqubo yokudibanisa emanzi ilula, kunye nokunamathiswa okuncinci, ixabiso eliphantsi, ukusebenza kakuhle kwe-composite, kwaye ingabandakanyi i-solvent eseleyo.

Umatshini we-laminating omanzi odibeneyo kunye nomgaqo osebenzayo osetyenzisiweyo kunye nendlela edibeneyo eyomileyo iyafana, umahluko yi-substrate yokuqala eqatywe ngeglu, okokuqala kunye ne-substrate yesibini edibeneyo edibeneyo, kwaye yomiswe yi-oven. Idosi elula, encamathelayo encinci, isantya sokudibanisa, iimveliso ezihlanganisiweyo aziqulathanga izinyibilikisi ezishiyekileyo, enye indlela yongcoliseko yokusingqongileyo.

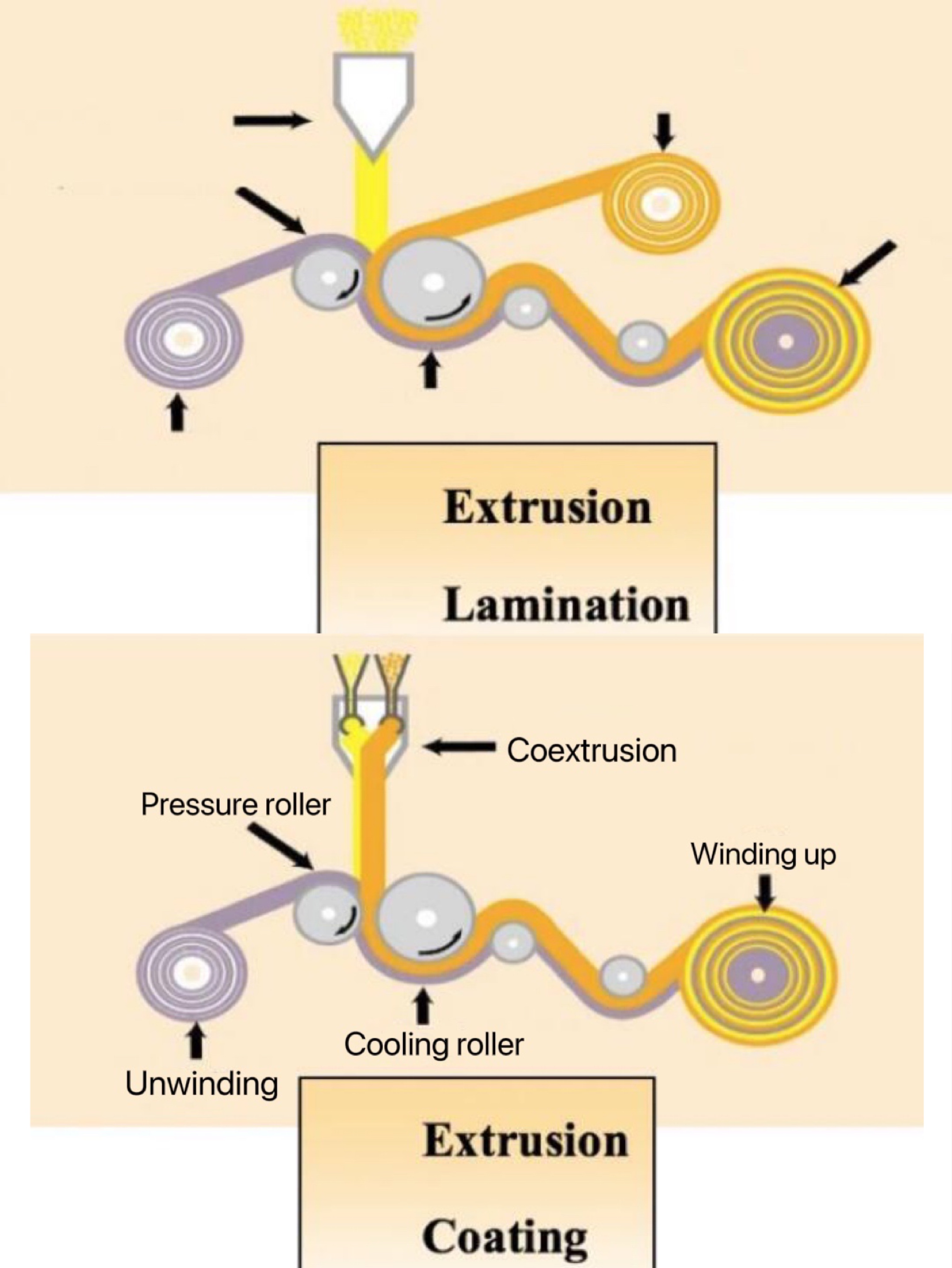

3. Ukudityaniswa kwe-Extrusion

I-Extrusion compounding yeyona ndlela ixhaphakileyo yenkqubo yokudibanisa, kukusetyenziswa kwe-resin ye-thermoplastic njengento ekrwada, i-resin ifudunyezwa kwaye inyibilika kwi-mold, ngumlomo wokufa endaweni yephepha lokunyanga ifilimu, ngokukhawuleza emva kokudibanisa nolunye uhlobo okanye iifilimu ezimbini kunye, kwaye emva koko zipholile kwaye zinyangekile. I-Multi-layer co-extrusion lamination yintlobo ngeentlobo zeepropathi zeplastiki ze-resin ngokusebenzisa ngaphezu kwe-extruder co-extrusion, kwi-die lamination kwifilimu.

Izinto ezihlanganisiweyo ziqhelene neengxaki ezisemgangathweni kunye nezisombululo

Ukudibanisa yinkqubo ebalulekileyo kwimveliso kunye nokupakishwa kokupakishwa okuguquguqukayo, ukusilela kwayo okuqhelekileyo oku: ukuveliswa kwamaqamza omoya, ukukhawuleza okuphantsi ukuya kokudibanisa, iimveliso ezigqityiweyo zishwabene kwaye ziqengqeleke, imveliso edibeneyo yolula okanye iyancipha, njl.

1, Isiganeko sokushwabana

Kwi-composite eyomileyo yokusilela kwesi siganeko sithatha umlinganiselo omkhulu wokungaphumeleli kuchaphazela ngokuthe ngqo umgangatho wemveliso egqityiweyo yokwenza isikhwama.

Ezona zizathu zokusilela zezi zilandelayo.

Umgangatho ombi wemathiriyeli edibeneyo okanye i-substrate yokushicilela ngokwayo, ukutenxa kubukhulu, imiqulu yefilimu ikhululekile kuzo zombini iziphelo kwaye iqinile kwelinye icala ngenxa yoxinzelelo olungalungelelananga lomoya. Ukuba umthamo wefilimu wahlulwe kwi-elasticity enkulu, kumatshini, ifilimu phezulu nangaphantsi kwaye i-amplitude yokubeka ekhohlo nasekunene nayo inkulu ngokwentelekiso kuba xa izinto zingena phakathi kwegubu elitshisayo kunye ne-roller cinezela eshushu, ayinakuba kumgangatho kunye neeroli ze-hot press, ngoko ayikwazi ukucudiswa tyaba, okubangela ukuba imveliso egqityiweyo ishwabene, ibangele ukushwabana kwemveliso. Xa izinto ezihlanganisiweyo ziyi-PE okanye i-CPP, ukuba ukuphambuka kobunzima kungaphezulu kwe-10μm, kulula ukushwabana, ngeli xesha, ukunyanzeliswa kwezinto ezidibeneyo kunokunyuswa ngokufanelekileyo, kwaye i-roller yokucinezela eshushu ingaba yimeko ethe tye kwi-extrusion. Nangona kunjalo, kufuneka kuqatshelwe ukuba ukuxhatshazwa kufuneka kube ngokufanelekileyo, ukuxinana okukhulu kulula ukwenza izinto ezihlanganisiweyo zibe nde, kubangele umlomo webhegi uthambekele ngaphakathi. Ukuba ukutenxa kobuninzi bezinto ezidibeneyo kukhulu kakhulu, akunakusetyenziswa ngokwenene, kufuneka kujongwe.

2. Amabala amhlophe ahlanganisiweyo

Ngenxa yezinga eliphantsi inki coverage amabala amhlophe: kuba inki emhlophe edibeneyo, xa inki ukufunxa volatilization kodwa hayi volatilization okubangelwa amabala amhlophe, ekhoyo ukuphucula ukomisa umthamo indlela; ukuba kusekho amabala amhlophe, isisombululo esiqhelekileyo kukuphucula ukugqunywa kwe-inki emhlophe, njengokujonga ukucoleka kwe-inki emhlophe, kuba ukucolwa kokucolwa kwereyithi yokugubungela i-inki elungileyo yomelele.

I-Adhesive endaweni yamabala amhlophe avelisiweyo ngokungafaniyo: kwi-inki ye-inki eqatywe ngeglu, ngenxa yokungena kwi-inki iyakufunxa i-solvent, i-top tension kunye nencinci kune-substrate, ukulinganisa akufanelekanga njengoko ifilimu ekhanyayo igqunywe ngeglue, i-glue depressions kunye ne-aluminium-plated surface okanye i-aluminium foil ayiyonto esondeleyo, ebonisa ukukhanya kwe-bubble okanye i-diff yamabala amhlophe. Isisombululo singasetyenziselwa ukulungelelanisa i-coating kunye ne-roller ye-rubber efanayo, okanye ukwandisa inani lokutshintshwa.

3. Iqamza elidityanisiweyo

Amaqamu ahlanganisiweyo aveliswa kwezi meko zilandelayo kunye neendlela ezihambelanayo.

Amaqamza adibeneyo kwisenzeko

1. ifilimu embi, kufuneka iphucule ukugxilwa kwe-adhesive kunye nobungakanani bokutshintshwa, i-MST, i-KPT surface ayilula ukumanzisa, kulula ukuvelisa amaqamza, ngakumbi ebusika. Amaqamza omoya kwi-inki,unakosebenzisa indlela yokwandisa ubuninzi be-adhesive ukususa.

2,Iqhuma lomphezulu we-inki kunye neqamza, kufuneka zidityaniswe ifilim edibanisa ubushushu kunye noxinzelelo oludityanisiweyo lokunyuka.

I-3, Isixa sokongeza iglue phezu kwe-inkino ephantsi, kufuneka inyuse i-compounding roller pressure paste time kunye nokusetyenziswa kwe-roller smooth, ifilimu i-preheating ngokwaneleyo ukunciphisa isantya sokudibanisa, khetha i-glue yokumanzisa kakuhle kunye nokukhetha okuchanekileyo kweyinki.

4. Izongezo (i-lubricant, i-agent ye-antistatic) kwifilimu ifakwe kwi-glue, ngoko ke kufuneka ukhethe iglue enobunzima obuphezulu be-molecular kunye nokuphilisa ngokukhawuleza, ukwandisa ukuxinwa kweglue, ukuphakamisa ubushushu be-oven ukuze umise ngokupheleleyo iglue, kwaye ungasebenzisi ifilimu kunye nexesha elingaphezu kweenyanga ezi-3 zokubeka, kuba unyango lwe-corona lulahlekile.

5,Iqondo lokushisa ebusika liphantsi, ukudibanisa kwifilimu kunye nokudluliselwa kwe-inki, ukuseta kwakhona isiphumo sokulungelelaniswa asilungile, ngoko indawo yokusebenza igcina ubushushu obuthile.

6,Iqondo lokushisa lokumisa liphezulu kakhulu, i-blistering ye-adhesive okanye i-crust of the surface skins iyenzeka, kwaye ngaphakathi angomile, ngoko ke ukushisa kwe-adhesive kufuneka kulungiswe.

7. Umoya ufakwe phakathi kwefilimu ye-roller edibeneyo, ukushisa kwee-roller ezidibeneyo kufuneka kwandiswe kwaye i-angle edibeneyo kufuneka ichithwe (ifilimu inzima kwaye kulula ukuvelisa ama-bubbles xa kunzima).

8,Ngenxa yesithintelo sefilimu ephezulu, igesi ye-CO2 eveliswa yi-adhesive curing, intsalela kwifilimu edibeneyo, engaprintwa kwi-bubble, kufuneka iphucule inani le-agent ephilisayo, ukwenzela ukuba i-adhesive igubungele kwindawo eyomileyo.

9. I-asidi ye-glycolic kwi-rubber i-solvent efanelekileyo ye-ink filler, i-rubber iyayichitha i-inki, kwaye kukho iibhubhu kuphela kwi-inkino, ekufuneka igweme ukungena kwamanzi kwi-rubber kwaye iphucule ukushisa kokumisa kwerabha ukunciphisa ukuchithwa kweyinki.

4. Amandla amaxolo amancinane

Amandla e-Peel ahluphekile, ngenxa yokunyangwa okungaphelelanga, okanye isixa seglue sincinci kakhulu, okanye i-inki esetyenzisiweyo kunye ne-adhesive ayihambelani nemeko, nangona ukunyanga kugqityiwe, kodwa phakathi kwemigangatho emibini yefilimu edibeneyo ngenxa yokungabikho kobude kuye kwanciphisa ukunciphisa amandla.

Isixa sokujova seglue sincinci kakhulu, umlinganiselo weglue uyancitshiswa, iglue iyonakaliswa kwindawo yokugcina, amanzi kunye notywala baxutywe kwiglue, abancedisi kwifilimu bayancitshiswa, inkqubo yokomisa okanye yokuvuthwa ayikho, njl., Okuya kukhokelela kwizinto zokugqibela zokunciphisa amandla e-peel composite.

Nika ingqalelo ukugcinwa okufanelekileyo kweglue, ixesha elide alikho ngaphezu kwe-1 unyaka (i-tin inokutywinwa); thintela izinto zangaphandle ukuba zingene kwiglue, ngakumbi amanzi, utywala, njl., ezinokubangela ukusilela kweglue. Ifilimu efanelekileyo yokuphucula inani le-glue yokugqoka; ukuphucula umthamo womoya wokomisa wokushisa, ukunciphisa isantya sokudibanisa. Unyango lwesibini lommandla wefilimu ukuphucula ukunyanzeliswa komhlaba; ukunciphisa ukusetyenziswa kwezongezo kwindawo yokudibanisa ifilimu. Zonke ezi ndlela zinokusinceda ukuba siphucule ingxaki yokungabi namandla kwamaxolo okudityanisiweyo.

5. Itywina lobushushu libi

Compound bag ubushushu itywina ukusebenza kakubi kunye nezizathu zayo ngokusisiseko ezi meko zilandelayo.

Amandla okutywinwa kobushushu akanamandla. Ezona zizathu zesenzeko azinyangeki ngokupheleleyo okanye ubushushu bokuvalwa kobushushu buphantsi kakhulu. Lungiselela inkqubo yokunyanga okanye ukonyusa ngokufanelekileyo ubushushu bemela yokutywina kunokuphucula ingxaki.

I-Delamination yesigqubuthelo sobushushu kunye nesalathiso se-refractive. Unobangela oyintloko wale nto kukuba i-bonding ayinyangwa. Lungisa ixesha lokunyanga okanye ukulungelelanisa umxholo wearhente yokunyanga unokuphucula le ngxaki.

Ukungavuleki kakuhle / ukungavuleki kakuhle kwefilimu yomaleko wangaphakathi. Unobangela wale nto yi-arhente yokuvula encinci kakhulu, ekhokelela kwizinto ezininzi (i-modifier) kunye nefilimu encangathi okanye enamafutha. Le ngxaki inokuphuculwa ngokunyusa inani le-arhente yokuvula, ukulungelelanisa inani le-modifier, kunye nokuphepha ukungcola okwesibini kwifilimu.

Isiphelo

Enkosi ngokufunda kwakho, sinethemba lokuba sinalo ithuba lokuba ngamaqabane akho.

Ukuba unombuzo ofuna ukuwubuza, nceda uzive ukhululekile ukusazisa kwaye uqhagamshelane nathi.

Qhagamshelana:

Idilesi yemeyile :fannie@toppackhk.com

Whatsapp : 0086 134 10678885

Ixesha lokuposa: Apr-01-2022