The packaging of Snack plays an effective and key role in advertising and brand promotion. When consumers buy snacks, the beautiful packaging design and the excellent texture of the bag are often the key elements to stimulate their desire to buy.

What is the common snack packaging bag type?

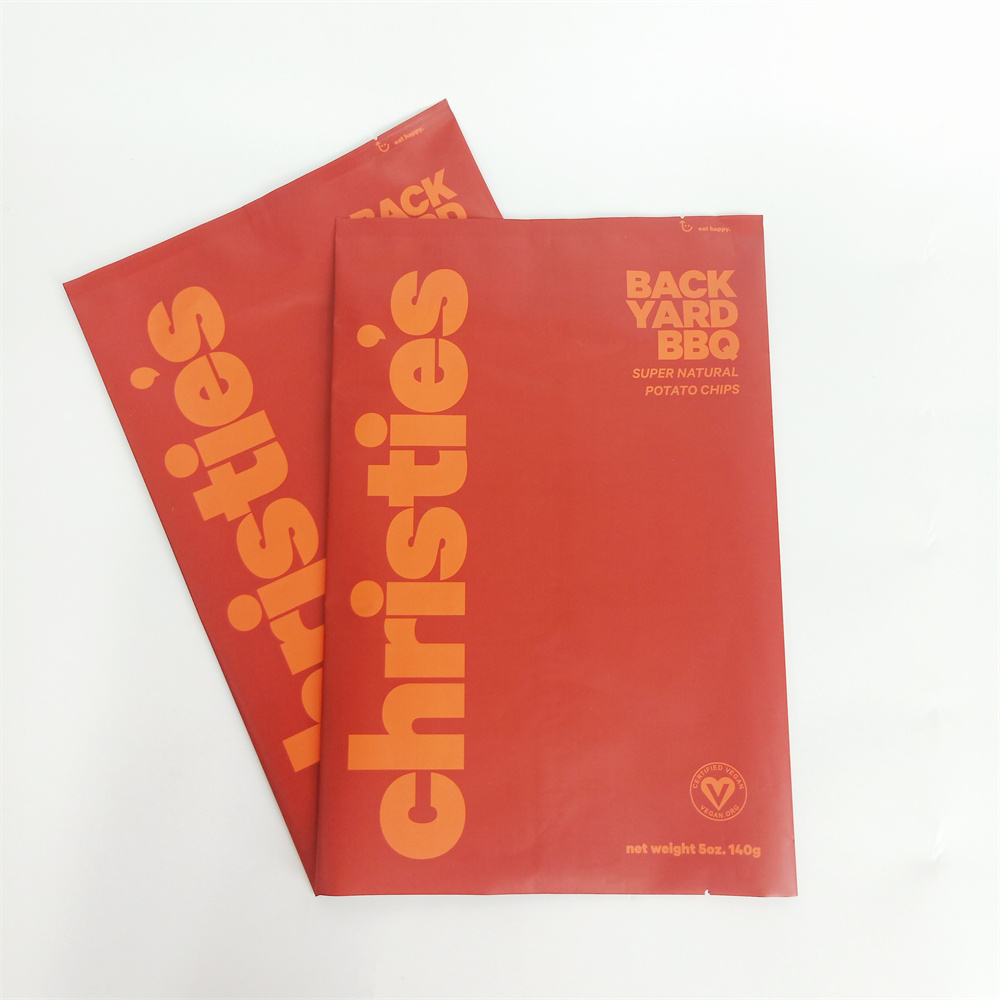

Snack packaging bags, including three-side-seal bags, back-seal bags, zipper stand-up pouches and many other different styles. And potato chips commonly used packaging is the three-sided seal and back seal bags. How to explain these two types of bags? A simple understanding is that the three-sided bag is the bag three sides for heat sealing, while the back seal bag from the middle of the plastic packaging for heat sealing. The common feature is that only one opening is left, the product is loaded from the seal and sealed by machine, the product packaging is complete.

What is the difference between back seal bags and three side seal bags?

Back-sealed bags are also known as sealed bags, simply speaking is the back of the bag body for sealing bags, back-sealed bags are very wide range of applications, general candy, bagged instant noodles, bagged dairy products, etc. are used in such packaging forms.

Snack food packaging is now increasingly simple, the form of packaging fancy. Many rice bags are getting smaller and smaller, and the material of the bag is becoming more and more. The use of back-sealed bags packaging snacks on the one hand can be a good guarantee of the quality of snacks, to avoid snacks subject to moisture. On the other hand, back-seal bag packaging is not only small and convenient, in terms of customer's purchase and carry and beautiful.

Back-sealed bags can be used as food bags, mainly for product packaging, storage of food, medicine, cosmetics, frozen food, postal products, etc., moisture-proof, waterproof, insect-proof, prevent things from falling apart, can be reused, a gentle press will be sealed tightly, non-toxic and tasteless, good flexibility, sealing arbitrary, very convenient.

About the introduction of three-side-seal bags, three-side-seal bags have the best airtightness, pumping real bags usually must be used in this bag-making method.

Three-sided sealed bags in many cases need to use vacuum packaging, this reason is also very diverse, some times may be to prevent food spoilage, some times Ken that is to make the shelf life longer. Vacuum packaging is also commonly referred to as decompression packaging, mainly is the bag of all the air is extracted and then sealed, making the bag has been in a highly decompressed state.

Not only that, the use of three-sided seal package material loss is low, the machine uses prefabricated bags, the bag pattern is perfect, sealing quality is good, thus improving the product grade.

How to choose snack packaging? For example, potato chips?

Whether you need eye-catching graphic printing services or easy-to-tear packaging materials, Dingli Packaging can provide you with them. The high-barrier aluminum-plated material we use for potato chips (fries) packaging bags can block external moisture, thus maintaining the dry and crispy taste of chips. Because everyone wants to eat crispy fries, not wet and soft.

Our packaging materials meet food safety standards while meeting barrier properties and protecting products from being crushed or spoiled during transit and handling.

If you don't have an idea about the packaging of your product, our team of experts will work with you to design the right packaging structure for your chips to ensure that your chips stay crispy,. If your product uses quality and healthy ingredients, is tasty and healthy, and needs packaging to boost sales, then trust our team to produce high-quality packaging that you can match your brand with lifelike design printing effects and high-barrier packaging materials that bring out the best in your product through and through.

Articles that might interest you

Potato chip packaging at Top Pack

Talking about the role of food packaging bags

Products that might interest you

Custom Uv Printed Plastic Back Seal Bag for Chips Package Bag

Custom Printed Back Seal Bag for Chips Snack Package Bag

Post time: Dec-09-2022