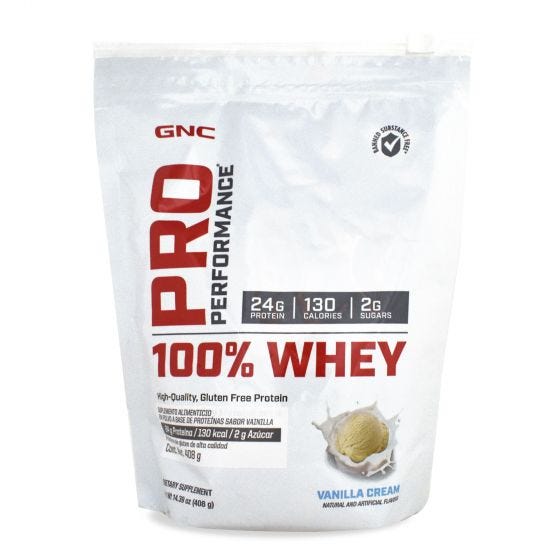

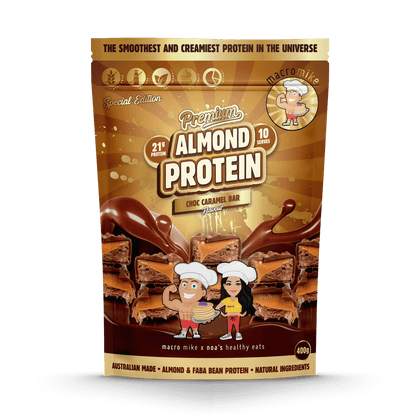

Sports nutrition is a general name, covering many different products from protein powder to energy sticks and health products. Traditionally, protein powder and health products are packed in plastic barrels. Recently, the number of sports nutrition products with soft packaging solutions has increased. Today, sports nutrition has a variety of packaging solutions.

The packaging bag containing protein bag is called flexible packaging, which mainly uses soft materials, such as paper, film, aluminum foil or metallized film. Have you ever wondered what the flexible packaging of protein bag is made of? Why each flexible packaging can be printed with colorful patterns to attract you to buy? Next, this article will analyze the structure of soft packaging.

Advantages of flexible packaging

Flexible packaging continues to appear in people's lives. As long as you walk into a convenience store, you can see flexible packaging with various patterns and colors on the shelves. Flexible packaging has many advantages, which is why it can be used in many different industries, such as food industry, electronics industry, medical beauty industry, daily chemical and industrial materials industries.

1. It can meet the diversified protection needs of commodities and improve the shelf life of commodities.

Flexible packaging can be composed of different materials, each with its own characteristics to protect the product and improve its longevity. Usually, it can meet the requirements of blocking water vapor, gas, grease, oily solvent, etc., or anti-rust, anti-corrosion, anti-electromagnetic radiation, anti-static, anti-chemical, sterile and fresh, non-toxic and non-polluting.

2. Simple process, easy to operate and use.

When making flexible packaging, a large number of flexible packaging can be produced as long as a machine with good quality is purchased, and the technology is well mastered. For consumers, flexible packaging is convenient to operate and easy to open and eat.

3. Especially suitable for sales, with strong product appeal.

Flexible packaging can be regarded as the most accessible packaging method because of its lightweight construction and comfortable hand feel. The feature of color printing on the packaging also makes it easy for manufacturers to express the product information and features in a complete manner, attracting consumers to buy this product.

4. Low packaging cost and transportation cost

Since most of the flexible packaging is made of film, the packaging material occupies a small space, the transportation is very convenient, and the total cost is greatly reduced compared with the cost of rigid packaging.

Characteristics of flexible packaging printing substrates

Each flexible package is usually printed with many different patterns and colors to attract consumers to buy the product. The printing of flexible packaging is divided into three ways, namely surface printing, inner printing without compounding and inner printing compounding. The surface printing means that the ink is printed on the outer surface of the package. The inner printing is not compounded, which means that the pattern is printed on the inner side of the package, which may be in contact with the packaging. The base layer of composite base material packaging and printing is also distinguished. Different printing substrates have their own unique characteristics and are suitable for different types of flexible packaging.

1. BOPP

For the most common flexible packaging printing substrate, there should be no fine pits during printing, otherwise it will affect the shallow screen part. Special attention should be paid to heat shrinkage, surface tension and surface smoothness, the printing tension should be moderate, and the drying temperature should be lower than 80 °C.

2. BOPET

Because PET film is usually thin, it requires a relatively large tension to make it during printing. For the part of ink, it is best to use professional ink, and the content printed with general ink is easy to be removed. The workshop can maintain a certain humidity during printing, which helps to endure higher drying temperatures.

3. BOPA

The biggest feature is that it is easy to absorb moisture and deform, so pay special attention to this key when printing. Because it is easy to absorb moisture and deform, it should be used immediately after unpacking, and the remaining film should be sealed and moisture-proof immediately. The printed BOPA film should be immediately transferred to the next program for compound processing. If it cannot be compounded immediately, it should be sealed and packaged, and the storage time is generally not more than 24 hours.

4. CPP, CPE

For unstretched PP and PE films, the printing tension is small, and the overprinting difficulty is relatively large. When designing the pattern, the deformation amount of the pattern should be fully considered.

Structure of flexible packaging

As the name suggests, flexible packaging is made up of different layers of material. From a simple architecture point of view, flexible packaging can be divided into three layers. The outermost layer material is usually PET, NY(PA), OPP or paper, the middle layer material is Al, VMPET, PET or NY(PA), and the inner layer material is PE, CPP or VMCPP. Apply adhesive between the outer layer, the middle layer and the inner layer to bond the three layers of materials to each other.

In daily life, many items need adhesives for bonding, but we seldom realize the existence of these adhesives. Like flexible packaging, adhesives are used to combine different surface layers. Take Garment factory as an example, they know the structure of flexible packaging and different levels best. The surface of flexible packaging needs rich patterns and colors to attract consumers to buy. During the printing process, the color art factory will first print the pattern on a layer of film, and then use the adhesive to combine the patterned film with other surface layers. Glue. The flexible packaging adhesive (PUA) provided by Coating Precision Materials has excellent bonding effect on various films, and has the advantages of not affecting the printing quality of ink, high initial bonding strength, heat resistance, aging resistance, etc.

Post time: Nov-05-2022