Composite packaging roll film (laminated packaging roll film) material has become increasingly popular in recent years due to its versatile usage and efficient performance. This type of packaging material is composed of multiple layers of various materials that work together to create a durable and effective barrier against external elements.

The function of composite packaging roll film material lies in its ability to protect and preserve the contents within the package. This type of packaging is often used for food products, pharmaceuticals, and other sensitive materials that require a long shelf life and protection from moisture, light, and oxygen. The layers of the composite material work together to create a barrier that prevents the contents from being affected by external factors.

Composite packaging roll film is widely used in various industries such as food, pharmaceuticals, and consumer goods. The packaging helps to protect the products from external factors and keep them fresh for longer periods.

Material Structure of Composite Packaging Film

The composite packaging roll film is a type of packaging film that is composed of two or three layers. The two-layer or three-layer structure of the composite packaging roll film is usually combined by a composite process. Among them, the two-layer structure is generally composed of two different materials.

The most commonly used materials for the layers of composite packaging films are polyethylene, polypropylene, polyester, nylon, aluminum foil, and paper. Polyethylene and polypropylene provide excellent moisture and chemical resistance, while polyester provides strength and stability. Aluminum foil is an excellent barrier for gases and light, while nylon provides a high oxygen barrier.

The first layer of the two-layer structure is usually made of a plastic film such as polyethylene or polypropylene. The second layer is a barrier material such as PET, or nylon. The barrier layer provides protection against moisture, oxygen, and other elements that can damage the product. The two layers are then laminated together using a special adhesive to create a strong, durable composite film.The two-layer structure of composite packaging roll film has many advantages. For example, it is lightweight, strong, and flexible. It is also waterproof, heat-resistant, and has good barrier properties against oxygen and moisture. These properties make it ideal for packaging products that require protection from the environment.

The three-layer structure of composite packaging roll film is similar to the two-layer structure, but it has an additional layer that provides extra protection. The additional layer is usually a middle layer made of a different material such as Aluminum foil or metalized foil. This layer provides better barrier properties against moisture and oxygen than the two-layer structure. This makes it ideal for packaging products that require additional protection, such as sensitive electronic components, medical devices, or pharmaceuticals.

The composite process used to create the two-layer or three-layer structure of composite packaging roll film is a complex process that requires advanced technology and equipment. It involves combining different plastics and barrier materials to create a strong, durable film. The process also includes adding special additives such as anti-static agents or UV stabilizers to improve the film's properties.

In addition to its protective properties, composite packaging roll film is also widely used because it is cost-effective and easy to manufacture. The composite process used to create the film is highly automated, which helps to reduce labor costs and increase production efficiency. It also allows manufacturers to produce large quantities of film quickly and consistently.

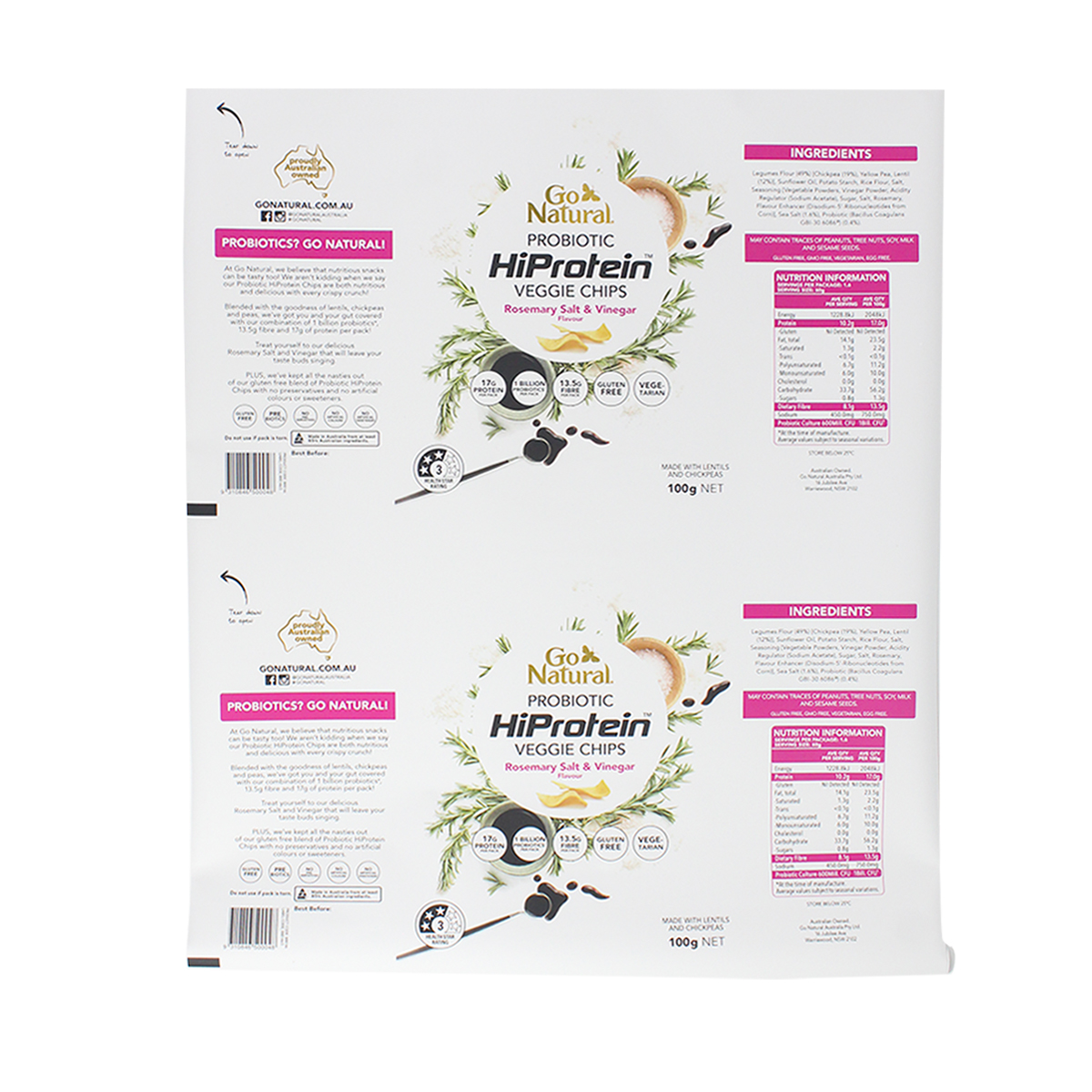

Application Scope of Composite Packaging Film

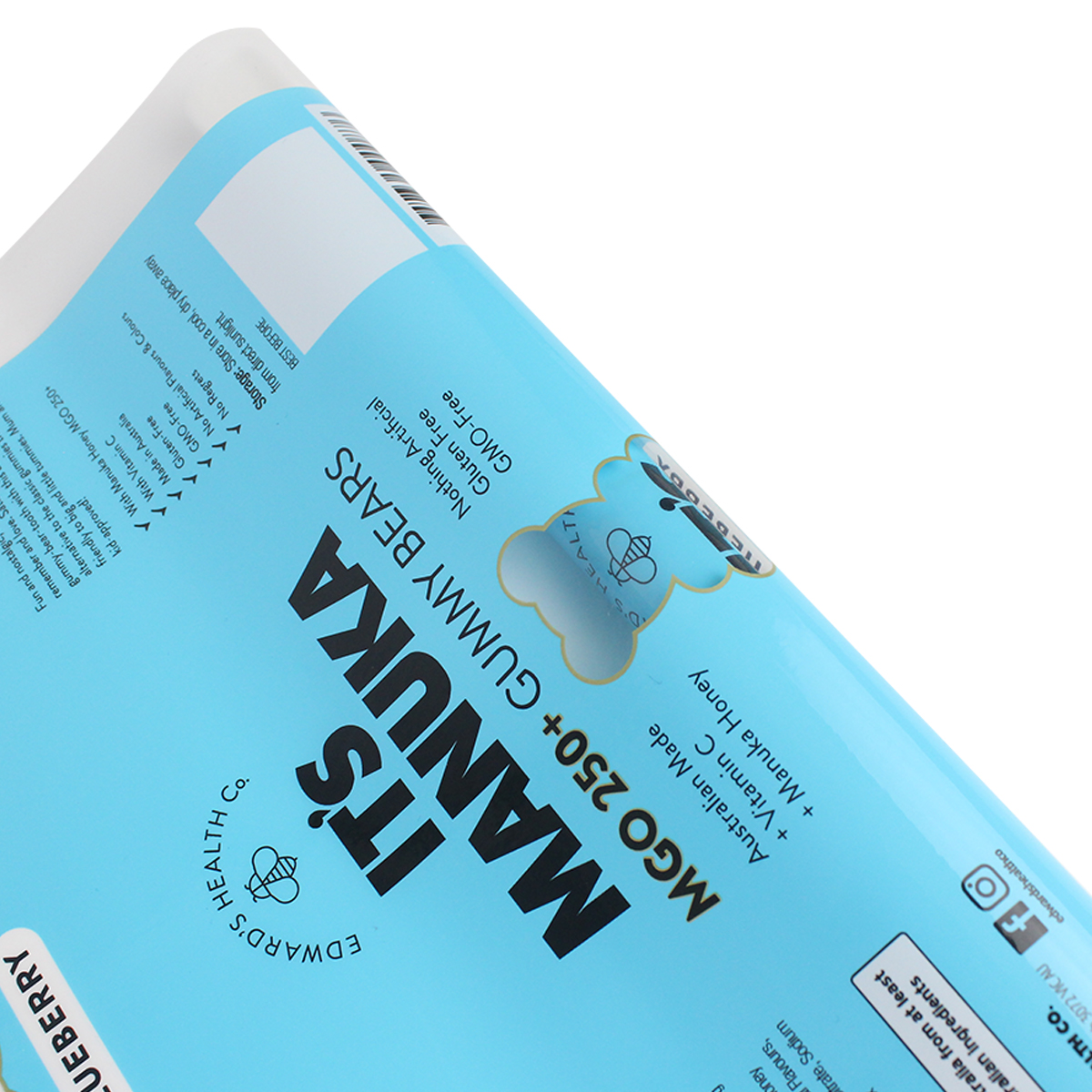

One of the most popular applications of composite packaging material roll film is in the food industry. This type of packaging is ideal for keeping food fresh and safe for consumption over an extended period. The packaging material can be customized to meet specific requirements for preserving different types of food, including frozen food, dry food, and even perishable items.

Another application of composite packaging roll film material is in the pharmaceutical industry, where sensitive drugs and medical devices are packed to prevent damage during transportation and storage. The packaging material's unique barrier properties ensure that the contents of the package are not contaminated by external factors such as oxygen, moisture, and light, which can affect medical products' efficacy.

Composite packaging roll film material is used in other industries as well, such as electronics, where sensitive equipment must be packed carefully to prevent damage. The material is also used in the automotive industry for packaging spare parts and other components that need to be transported over long distances.

The use of composite packaging roll film material has several advantages over other types of packaging. The material is lightweight, durable, and cost-effective, making it an efficient choice for businesses. Moreover, the composite material can be customized to meet specific packaging requirements, ensuring that the contents of the package are protected from external factors.

Moreover, composite packaging roll film material is an eco-friendly alternative to traditional packaging. The material can be recycled, reducing its impact on the environment. Many businesses are now turning to eco-friendly packaging options to reduce their carbon footprint and promote sustainability.

In conclusion, composite packaging roll film material is a versatile and efficient solution for packaging needs across various industries. Its unique properties make it an ideal choice for businesses looking to protect and preserve their products during transportation and storage. The material's cost-effectiveness, customization options, and eco-friendliness make it an attractive option for businesses looking to reduce packaging costs and promote sustainability. As demand for high-quality packaging continues to grow, composite packaging roll film material will continue to play a vital role in the packaging industry's future.

Post time: Mar-23-2023