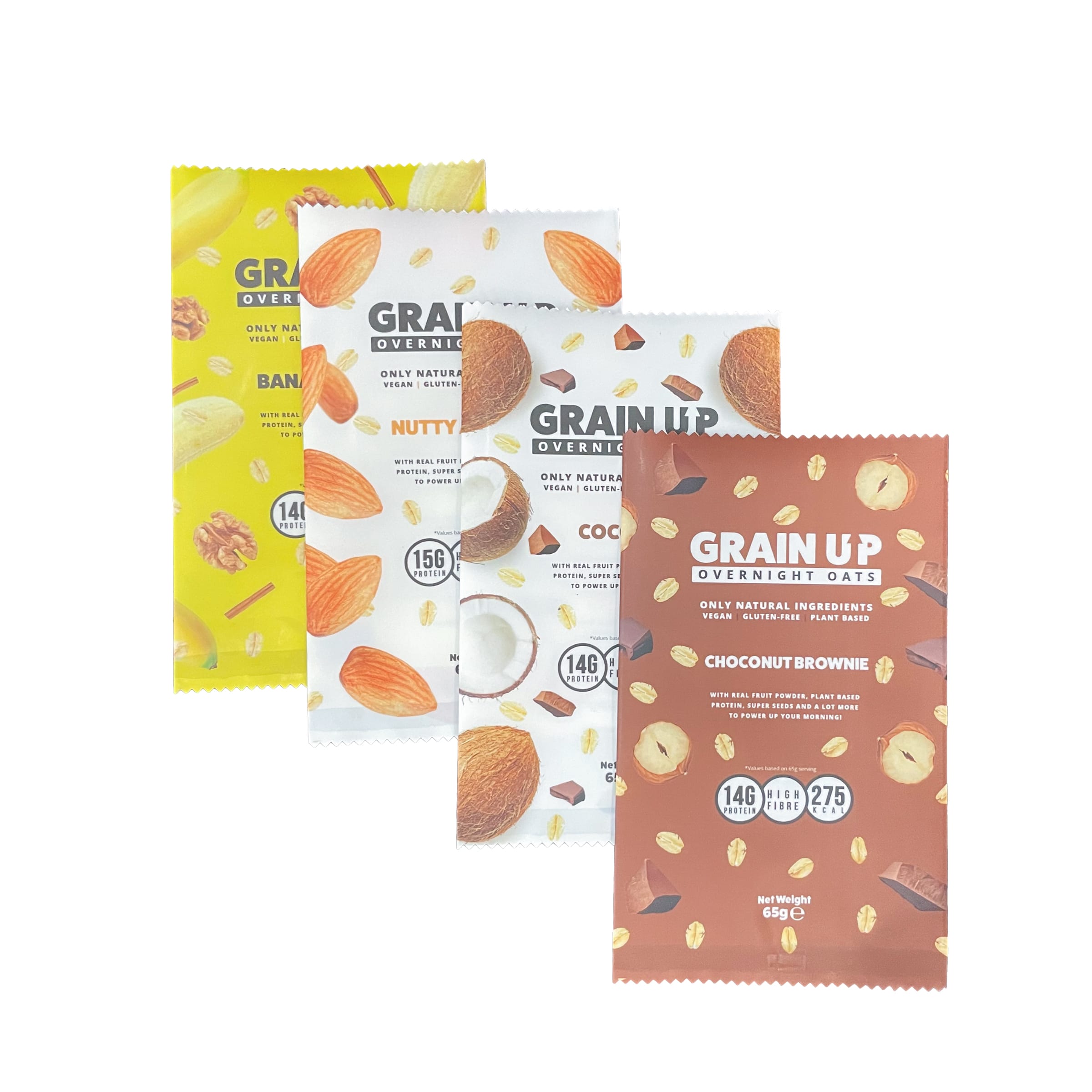

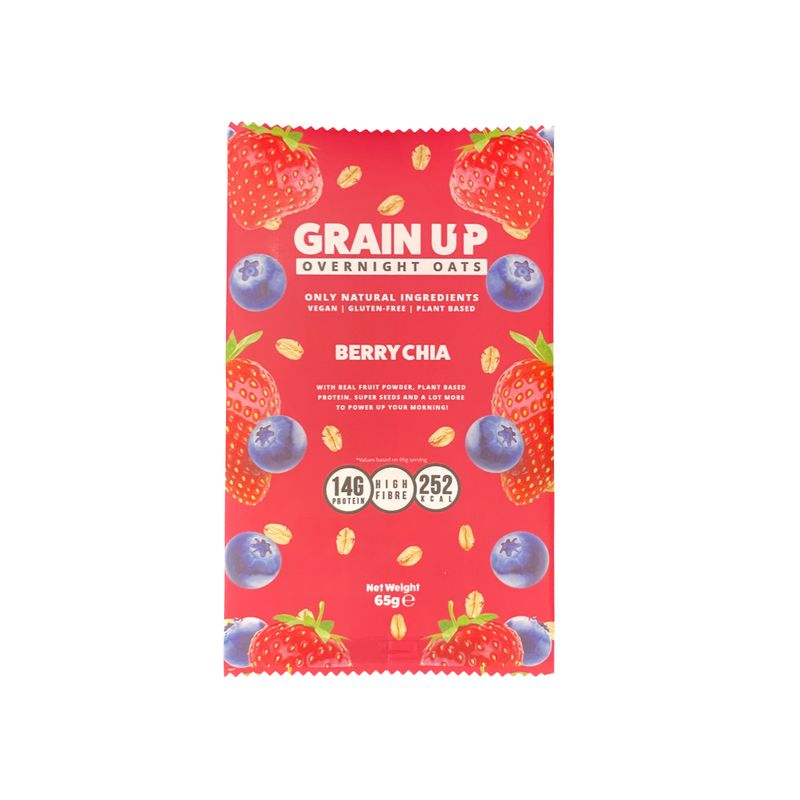

Is your food packaging helping your product, or is it putting it at risk? If you're a food brand or a packaging buyer, this is something you should think about. Rules are getting stricter, and customers are paying more attention. Food safety is no longer a bonus—it’s a must. If your current pouches let in air, light, or moisture and ruin your organic oats, or if your supplier can't keep quality steady, it’s time to look for a new option. At DINGLI PACK, we make food-grade custom pillow pouch packaging with centre seal and logo printing that works well for foods like organic oats. We don’t just sell bags. We help you keep your food fresh, safe, and attractive on store shelves.

What Does "Food Safe" Packaging Mean?

It means the packaging won’t leak harmful stuff into your food. Good food-safe packaging keeps your food safe, blocks air and moisture, and follows safety rules like those from the FDA, EFSA, or GB. The goal is simple: protect the food and the people who eat it. This is true for dry foods like grains and oats, and also for snacks, cookies, and other items that go straight into people’s mouths.

Why Should You Care About Packaging Safety?

Your Customer’s Health Comes First

Bad materials can release chemicals like BPA, phthalates, or metals. These are dangerous over time. If you run a brand, your packaging must be safe and help your customers feel safe too. Your end customer expects the product inside to be just as safe as it is tasty.

Better Packaging Keeps Food Fresh

Good packaging holds flavor, crunch, and smell. Your oats won’t last if the bag lets in moisture. A strong pouch keeps your product in top shape. Even in transit or storage, a strong barrier layer matters.

Bad Packaging Hurts Your Brand

If your packaging fails, people will notice. Recalls and bad reviews can cost a lot. Today’s customers check labels—and they care how their food is packed. They also tell others quickly when something goes wrong. One small mistake can impact your brand’s image across multiple markets.

What Makes Packaging Safe for Food?

1. Certified Food-Grade Materials

Not all materials are safe for food. We use BPA-free films that meet FDA and EU rules. Whether you pick stand-up pouches, spout bags, or flat pouches, every layer must be food-safe. Certification is not optional—it is a must-have for every serious food business.

2. Safe Inks and Glues

Your logo ink and the glue between pouch layers matter. They should be tested and approved. We use water-based inks that are safe for food packaging. No smell, no toxic reaction, and clear brand display.

3. Strong Barriers

Organic oats are sensitive. Our pillow pouches have layers that block air and moisture. This helps keep the oats fresh longer. Barrier strength is important not just for freshness, but for preventing spoilage that leads to waste or complaints.

4. Follows Global Rules

We meet international standards like REACH and BRC. If you're in Europe, this means fewer problems when you grow your business. If you export, your packaging will still comply.

Are “Natural” or “Recycled” Bags Always Safe?

No, not always. Some recycled paper or plastic isn't safe for direct food contact. A bag can be green but still unsafe. What matters is proper testing and proof. Even “natural” materials can break down or react in unwanted ways.

At DINGLI PACK, we mix safety with eco-friendly choices. From zipper pouches to kraft bags for cookies and snacks, we make sure each item is okay to touch food. Our team can help you choose packaging that meets both safety and sustainability goals.

What Should a Good Packaging Supplier Offer?

A good supplier should give you more than just a price list. Here's what to expect:

- Proof of Safety: This means actual certificates like FDA, ISO 22000, BRC, and EFSA. You should be able to see them and understand what they cover. Ask for them directly. A real partner will not hesitate to show proof.

- Test Reports: Your supplier should have data on chemical migration, moisture barrier strength, and seal strength. This shows that the packaging was tested and passed. These tests should match the needs of your product, especially if it's sensitive like oats or snacks.

- Product Fit: Can they make the right pouch for your food? Do they offer options like resealable zippers, custom sizes, or extra barrier layers? Custom options let you design packaging that works, not just something generic.

- Scalability and Flexibility: You might start with 5,000 pouches and grow to 500,000. Can your supplier scale up with you? Can they handle small test runs for new products? XINDINGLI PACK offers low minimum order quantities for startups and quick lead times for growing brands.

- Easy Communication: You shouldn’t wait days for an answer. Your supplier should respond fast and clearly. If you have a problem, they should help you solve it—not send you in circles.

At DINGLI PACK, we do more than make bags. We guide you from the first sample to large-scale production. Our team explains materials, tests samples, and checks the design to avoid delays. We listen to your needs. We offer ideas. We make the whole process easier. Whether you're just starting or already selling across Europe, we’re here to help.

Post time: Jul-21-2025